Neutrase protease Sunson® PRN60

PRODUCT DESCRIPTION

The neutral protease is produced by submerged fermentation of Bacillus subtilis followed by purification and formulation. The product It is used in ethanol fermentation, leather softening and depilation, silk degumming, plant and animal proteolysis, brewing and feed additives etc..

MECHANISM

The Neutral Protease catalyzes the hydrolysis of protein to produce free amino acids and short peptides within a pH range from weak acid to weak alkaline environment. Besides the main activity of endo-peptidase, the product also contains exo-peptidase, whose joint actions leads to liberation of short peptides and free amino acids.

REACTION PARAMETERS

|

PARAMETERS |

RANGE |

|

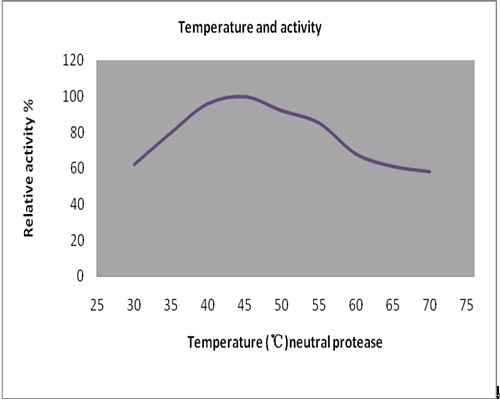

Activity Temperature |

30℃-55℃ |

|

Optimum Temperature |

40℃-50℃ |

|

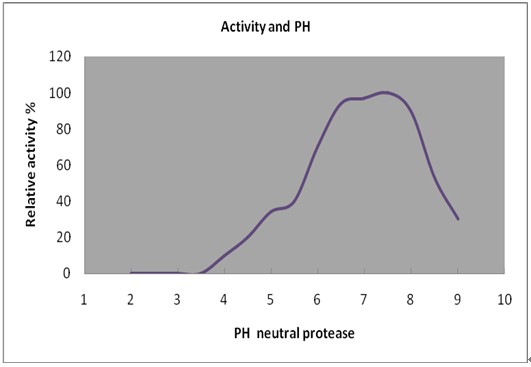

Activity pH |

5.5-8.5 |

|

6.5-7.5 |

PRODUCT SPECIFICATION

|

Items |

Description |

|

Declared Activity* |

60,000u/g |

|

Physical Form |

Powder |

|

Color** |

Light brown |

|

Odour |

Normal microbial fermentation odour. |

*Definition of Unit: 1 unit of Neutral Protease equals to the amount of enzyme, which hydrolyzes casein to get 1μg of tyrosine at 30℃ and pH7.5 in 1 min.

** Color: Color can vary from batch to batch. Color intensity is not an indication of enzyme activity.

BENEFITS:

1.In brewing industry:

• Improve yeast growth and speed up fermentation rate

• Increase alcohol yields and DDG protein value

• Reduce thin stillage viscosity and improved evaporation

• Whole-corn or grain starch saccharification

• Increase alpha-amino nitrogen

• Improve raw material utilization

2.In baking industry:

• Reduce the paste gluten,

• Reduce sodium pyrosulfite and SO2 ,

• Make biscuit into attractive golden color,

• Improve plasticity and physicochemical property ,

• Rectify the effect of flavor by chemical addition agent and enhance the quality .

PRODUCT STANDARD

The product complies with GB1886.174.

|

No. |

ITEMS |

INDEX |

|

|

1 |

Particle size (%<40 mesh) |

≥80 |

|

|

2 |

≤8.0 |

||

|

3 |

Lead/(mg/kg) |

≤5.0 |

|

|

4 |

Arsenic/(mg/kg) |

≤3.0 |

|

|

5 |

Total viable count/(CFU/g) |

≤50000 |

|

|

6 |

Coliform Bacteria/(CFU/g) |

≤30 |

|

|

7 |

Escherichia coli |

(CFU/g) |

<10 |

|

(MPN/g) |

≤3.0 |

||

|

8 |

Salmonella/(25g) |

Not Detected |

|

APPLICATION RECOMMENDATION

The recommended dosage is 0.05-3kg of the enzyme preparation per ton of total raw materials. The dosage has to be optimized based on each application, the raw material specifications, product expectation and processing parameters. It is better to begin the test with the convenient volume.

SAFE HANDLING PRECAUTIONS

Enzyme preparations are proteins that may induce sensitization and cause allergic type of symptoms in susceptible individuals. Prolonged contact may cause minor irritation for skin, eyes or nasal mucosa. Any direct contact with human body should be avoided. If irritation or allergic response for skin or eyes develops, please consult a doctor.

WARNINGS

Keep sealed after use every time to avoid microbial infections and inactivation of enzymes until its finish.

PACKAGE AND STORAGE

Ø Package: 25kgs/drum; 1,125kgs/drum.

Ø Storage: Keep sealed in a dry and cool place and avoid direct sunlight. Slight sedimentation is acceptable since it will not impact performance of the product.

Ø Shelf life: 12 months in a dry and cool place.

| E-mail: sunson@chinaenzymes.com |

| Tel:86-20-86586087 86-10-58246891 |

| Fax:86-20-86586895 86-10-58246862 |